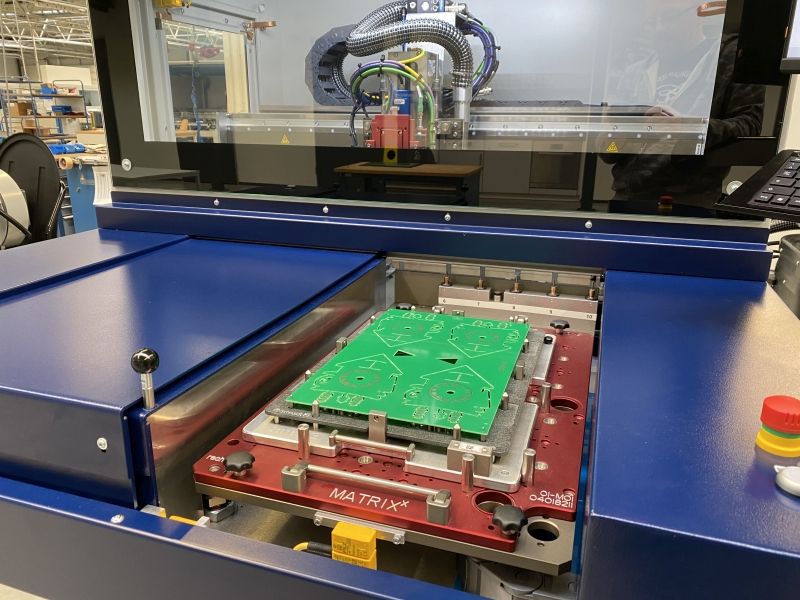

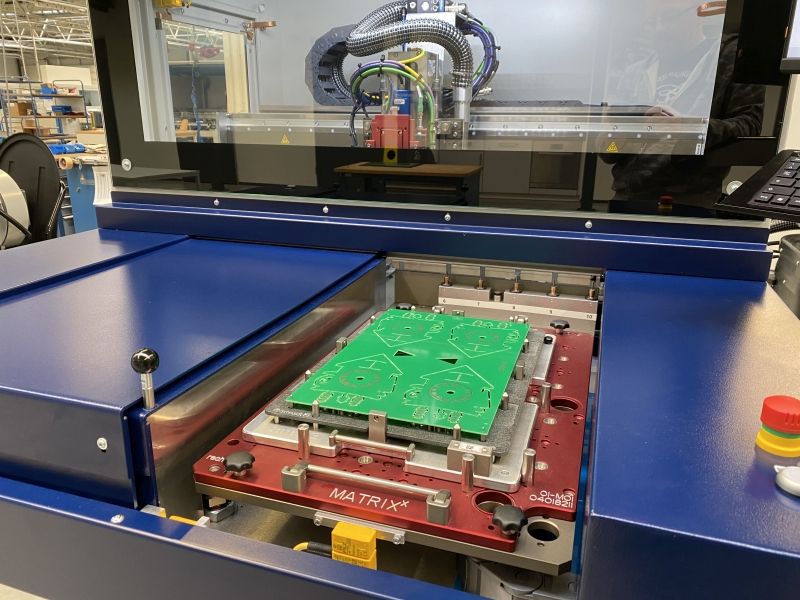

Depaneling SAR Compact

Economical depaneling system SAR-Compact

The SAR-Compact depaneling machine is an attractively priced solution for small to medium-sized batches with different to high product variations. The very high price-performance ratio of this machine was not checked by high-speed processes, but by a consensual value-analytical approach, which enables you to invest in your own machine while at the same time replacing all functions and that of the automotive industry.

Despite the low investment, the machine uses the latest drive technology and linear motor technology with high precision in the directions x, y and z. Nor are there any compromises in terms of flexibility.

Furthermore, our workpiece carrier solutions such as MAGNOPLATE and "do-it-yourself" can be used to enable the customer to work efficiently and flexibly in high-mix production.

Simple operation due to simple menu navigation, CAD / CAM programming and teach function.

Furthermore, our Werkstückträger-solutions can be used to enable the customer to work economically and flexibly in high-mix production.

Nutzentrenner SAR Compact

Technical data

-

Machine dimensions

Machine dimensions DepenelingData Value Unit Width + monitor 1300+300 mm Depth 1.607 mm Height 1.642 mm Operating height ca. 894 mm Weight 800 kg -

Supply

Necessary machinery supplyData Value Unit Input voltage 400 V Mains frequency 50 Hz Main fuse protection 16 A Compressed air (free of oil, filtered and dry) 0,6 (6) mPa (bar) Consumption approx. 140 l/min Ambient temperature + 18 bis + 40 °C Relative humidity 10 bis 80 % -

Noise level

measured strength of a soundData Value Unit Measured at a distance of 1.2 m from the machine < 72 dB (A) Measured at a distance of 1.2 m from the machine with soundproofing < 68 dB (A) -

Speed

Axis speedsData Value Unit Moving speed of linear axes 1..000 mm/s Moving speed of linear axes high speed 1..000 mm/s -

Levels of accuracy

Data Value Unit Repeat accuracy ± 0,02 mm Positioning accuracy ± 0,02 mm Milling accuracy with camera ± 0,1 mm Milling accuracy without camera ± 0,15 mm -

Rate of cutting / cycle time

Depanelling Capacity -

spindle and separating tool

End milling moduleData Value Unit Milling bit support Ø 3,175 mm Milling bit diameter Ø 1-2,5 mm Spindle speed of milling bits 0.28 KW bis 40.000 1/min Spindle speed of milling bits 0.5 KW bis 60.000 1/min Pneumatic clamping of end milling cutter -

Operating range

Operating range and PCB characteristics standard shuttle axisData Value Unit Max. milling range 430 x 350 mm Max. multi-panel size 350 x 430 mm Max. Nutzengröße 350 x 430 mm PCB thickness 0,5 - 3,2 mm Max. component height spindle 0.28 kW (top side) 10 mm Max. component height spindle 0.5 kW (top side) 20 mm Maximum component height (bottom side) 35 mm Max. erection height on workpiece carrier base plate 70 mm Max. distortion of PCB (of length or width) 1 % PCB materials CEM, FR4, IMS (AL), CU -

Shuttle system standard shuttle axis

Data Value Unit Exchange time for double shuttle < 2,5 seconds Standard size per workpiece carrier 1300 555 x 380 x 12 mm Product change time/tooling time < 4 min

The basic equipment consists of a milling spindle module. The milling head can optionally be upgraded with a vision system or scanner

By equipping it with two shuttle systems, the highest possible output is achieved by avoiding dead times

Nutzentrenner SAR Compact