Nutzentrenner made by SCHUNK

Depaneling SAR-1300 B2

The world’s most precise stand-alone depaneling machines with the widest range of workpiece holder solutions

100% variability, from batch size 1 to large-scale production

This SAR-1300 series is designed for small to large batch sizes with low to high product variance. Customers benefit from process reliability, low power consumption, and short cycle times. Due to the linear motor axes and modern control technology, milling accuracy is ±0.1 millimeters. And despite this performance, our universal depaneling machines are energy-saving. The technical availability is up to 99.8 percent.

Special features of the depaneling machine SAR-1300

-

Highest milling accuracy due to high-precision linear motor axes and state-of-the-art control technology

-

Panel feeding possible with one or two shuttle axles (2nd shuttle can be retrofitted)

-

Shortest cycle times due to high speed linear motor axes and minimized dead times

-

Maximized availability due to the use of high-quality components and a simple system design

-

Ergonomic operator height even with high assembly groups

-

The simple design allows a targeted initial investment with a wide range of expansion options

-

Short delivery times due to the use of identical components in the modular system and flow production

SCHUNK Electronic Solutions setzt Maßstäbe!

100 %

variability, from batch size 1 to large-scale production

variability, from batch size 1 to large-scale production

The world’s most precise stand-alone depaneling machines with the widest range of workpiece holder solutions

This SAR-1300 series is designed for small to large batch sizes with low to high product variance. Customers benefit from process reliability, low power consumption, and short cycle times. Due to the linear motor axes and modern control technology, milling accuracy is ±0.1 millimeters. And despite this performance, our universal depaneling machines are energy-saving. The technical availability is up to 99.8 percent.

Flexible and efficient

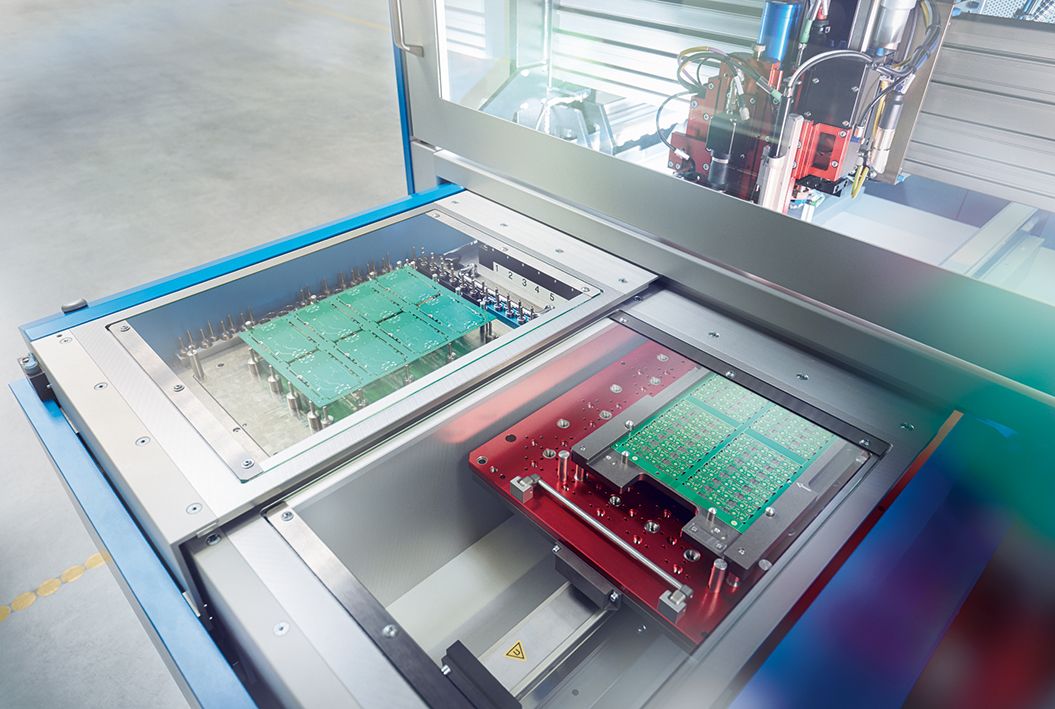

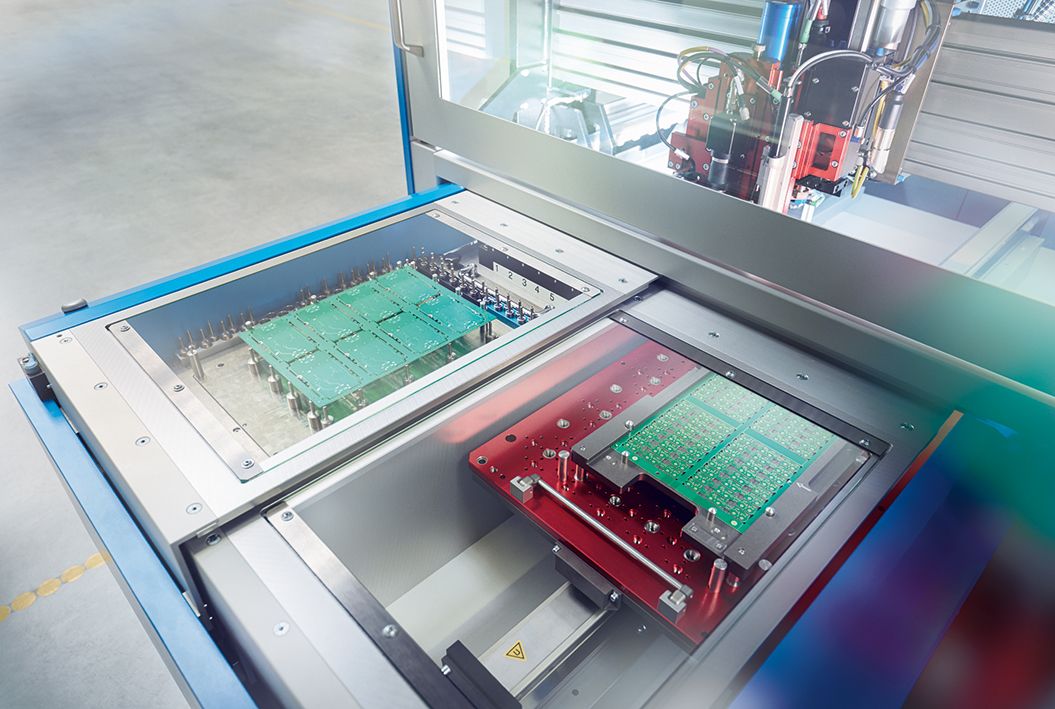

Standard version

The standard version of the SAR-1300-Uni has a high-performance single shuttle system.

shuttle system

When equipped with a dual shuttle system, the machine offers maximum output by avoiding time lags.

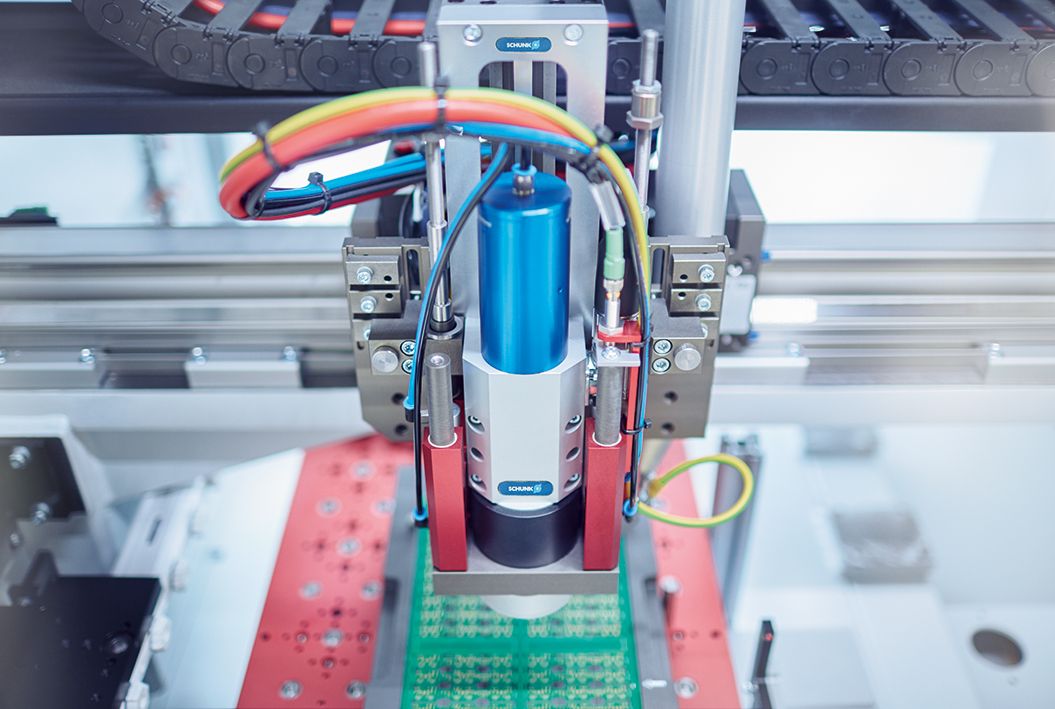

milling bit module

The basic configuration consists of a milling bit module. As optional expan-sion of the base system, the milling bit module is available with vision system as well as with scanner.

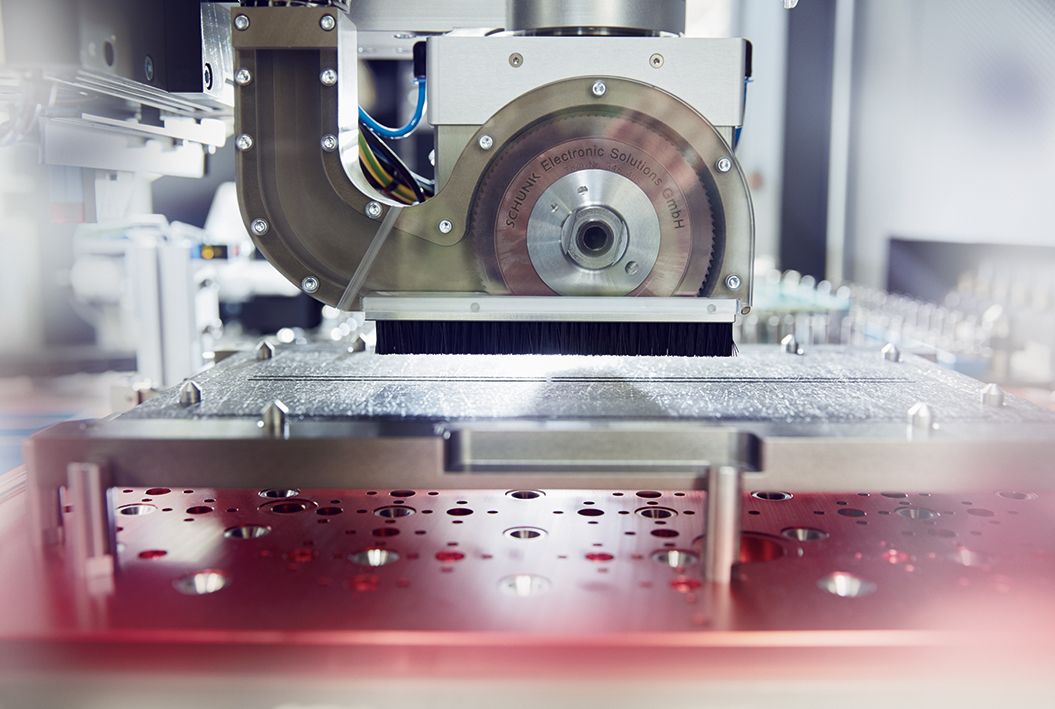

Sägespindelmodul

The machine can be optionally fitted with an additional sawing disc mod-ule. The second module can be retrofitted at any time.