Depaneling machine ILR 2800

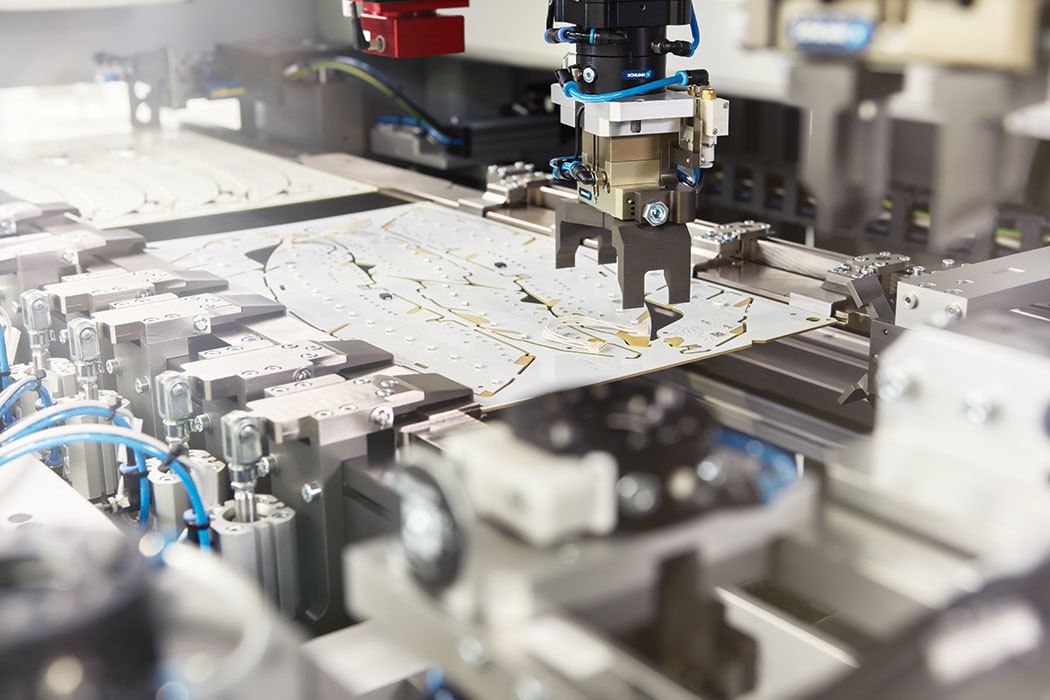

Inline depaneling machine ILR-2800-B and palletizer PAL-1400 for flexible, fully automatic cutting with optional palletizing.

The SCHUNK depaneling machine ILR-2800 with the optional palletizing system PAL-1400 guarantees maximum flexibility and minimum set-up times in connection with a gripper changing system. With the specially developed quick feeder and the use of highly dynamic drives with path control for cutting and PCB handling, the greatest possible throughput and maximum flexibility are achieved. The simple and weight-optimized design of the circuit board gripper significantly reduces tool costs.

Special features:

- Linear motor based fast-acting panel feeder for minimum loading times at the panel infeed

- Shortest depaneling times due to a highly dynamic linear motor milling gantry with special milling brush hold-down

- Short handling times for detached components achieved by linear motor based handling system with continuous path control

- Maximum flexibility and minimal set-up times due to simple and automatically exchangeable multi panel grippers

- Optional extension by an integrated palletizing system

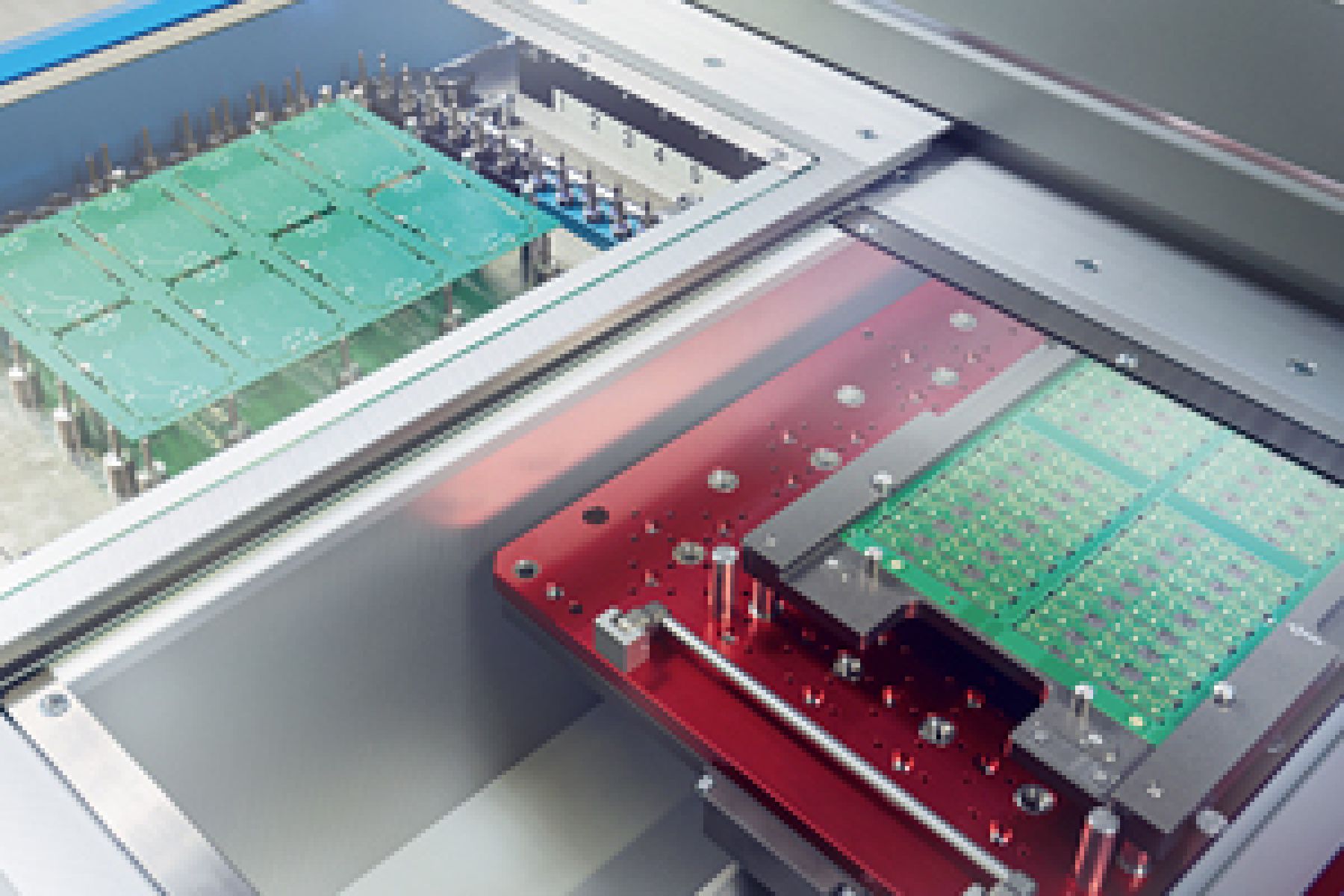

Inline depaneling machines can be equipped with a palletizing system PAL-1400 on request. The cut-out assembly groups can then be directly placed in trays with dimensions up to 600 x 400 mm for further processing. Trays can be fed using carriages or belts. A wide variety of pallet variants can be safely processed using optional pallet coding.

With the ILR 2200, the panels reach the inside of the machine in less than two seconds via a linear motor-driven fast feed. There a milling module separates the circuit boards with an accuracy of +/- 0.1 millimeters. Thanks to linear motor axes and modern control technology, the modules achieve a travel speed of two meters per second for milling and ten meters per minute for sawing. The machine has a modular structure, the first of its kind in the world. Electronics manufacturers buy inexpensive basic equipment and can upgrade the machine at any time - with milling and gripping modules, a camera system or a second or even third circuit board handling system that minimizes dead times.