-

The first collaborative loading process of depanelling machines

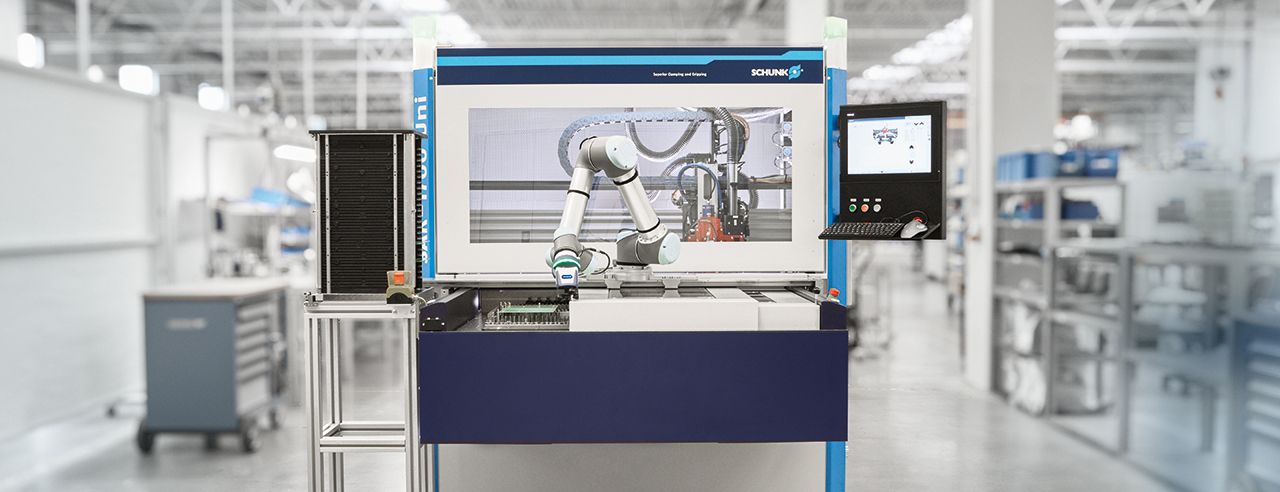

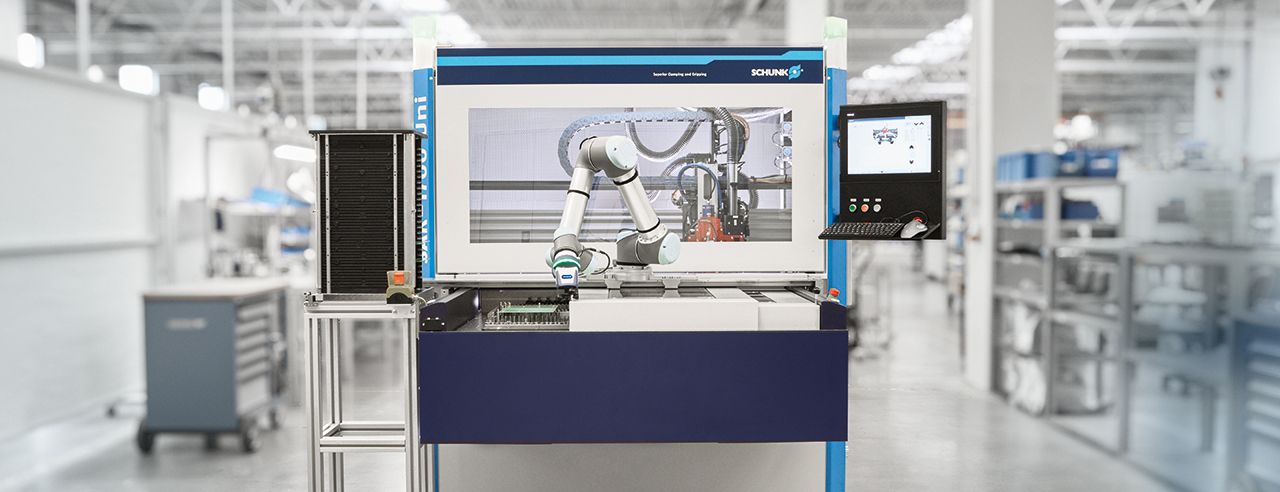

If required, a depanelling machine of the SAR 1700 series can be loaded with a robot arm and a SCHUNK Co-act EGP-C gripper for human/robot collaboration. High-speed linear motor axes ensure shortest cycle times. Greifer EGP-C aufgesetzt. -

Building depanelling machines according to the modular principle

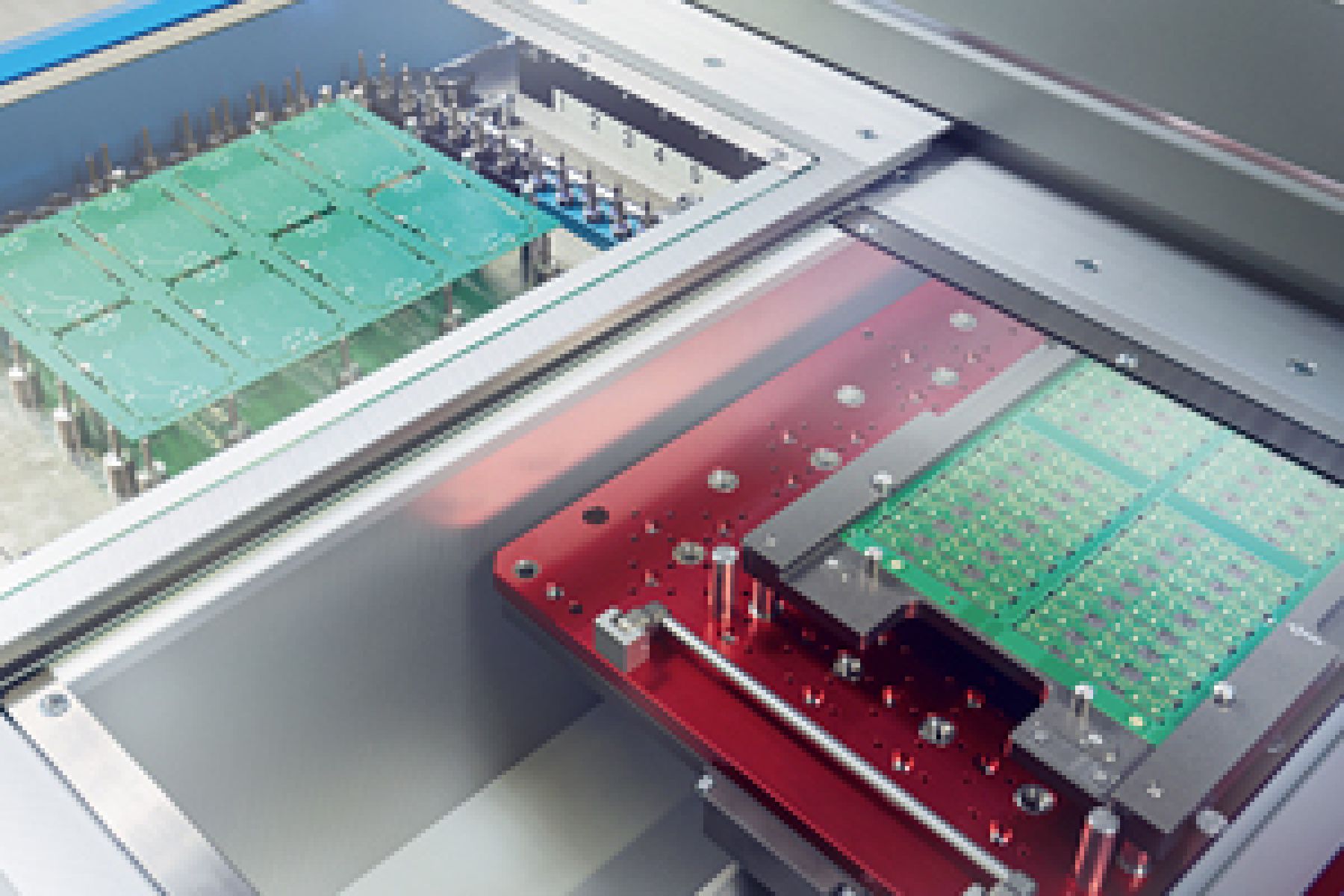

SCHUNK Electronic Solutions brings the ILR-2200 to the market: It is a fully automated inline depanelling machine that separates individual circuit boards from large entire PCBs (panel) using a milling module.

Depaneling machine from SCHUNK

SCHUNK Electronic Solutions is setting standards in the field of depaneling technology

As part of our innovative family-owned company, SCHUNK Electronic Solutions has been a leading manufacturer of linear motor axes for years, that are also used in our customized machines. In the machine area, our focus is on modern processes for electronic assembly production. Our systems and devices meet the most demanding requirements resulting from increasing miniaturization, the use of highly sensitive components, and the rising quality demands for printed circuit boards.

Our machines: Rapid and precise

- Stand-alone depaneling machine

- Inline depaneling machines

- Palletizer

- Exoten-Bauteilbestücker

Depaneling machines from SCHUNK Electronic Solutions are high-performance machines for the depaneling of single circuit boards with electronic components. The cutting principles we use are especially fast, reliable, and low-stress, and ensure maximum productivity and the best cutting quality.

Our product range focuses on modern processes in electronic component production. Our systems and devices meet the most demanding requirements resulting from increasing miniaturization, the use of highly sensitive components, and the rising quality demands for printed circuit boards.

Modularity for the Industry 4.0 era

SCHUNK Electronic Solutions is the world's first manufacturer to design modular depanelling machines. The advantage for electronic manufacturers: they can buy a basic version of the machine and then retrofit it later – such as with additional milling modules, a camera system or a robot arm that takes over the loading and unloading and reduces the personnel costs. "The depanelling machines require a low initial investment and grow flexibly along with companies", says Ehmer. "Companies gain future security for the Industry 4.0 era, where you need to economically manage small batch sizes and frequent product changes."

The devices hardly use any more energy than a microwave

Customers benefit from process reliability, low electricity consumption and short cycle times. The SAR-1300-Mono-Smart achieves separation efficiency of up to four meters a minute and thanks to the linear motor axes and modern control technology, the milling accuracy is +/- 0.1 millimeter. The SAR-1700 achieves the milling speed of the SAR-1300-Mono-Smart and also saws with a speed of up to ten meters per minute. And it even energy saving, despite this performance. The power consumption of the SAR 1700 is 800 Watt, that of the SAR 1300 is only 700 Watt, which approximately corresponds to a microwave. The technical availability is up to 99.8%.

SCHUNK Electronic Solutions offers solutions for the entire spectrum of the depaneling operation

SCHUNK Electronic Solutions setzt Maßstäbe!

SCHUNK Electronic Solutions GmbH

Wie Sie uns finden